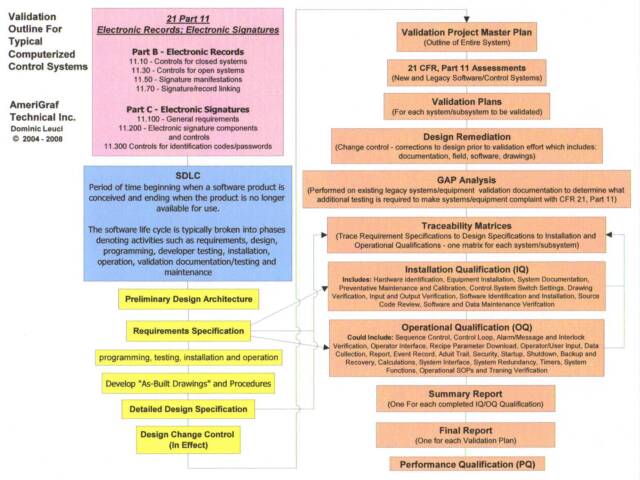

Validation Outline for Typical Computerized Control System

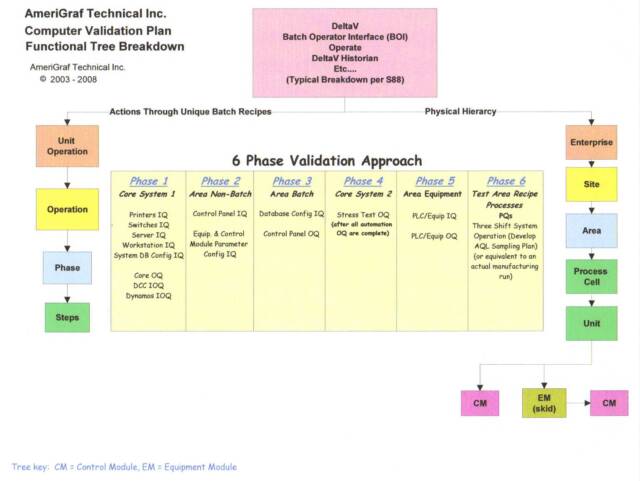

Typical Computer Validation Plan - Delta-V Control - Manufacturing

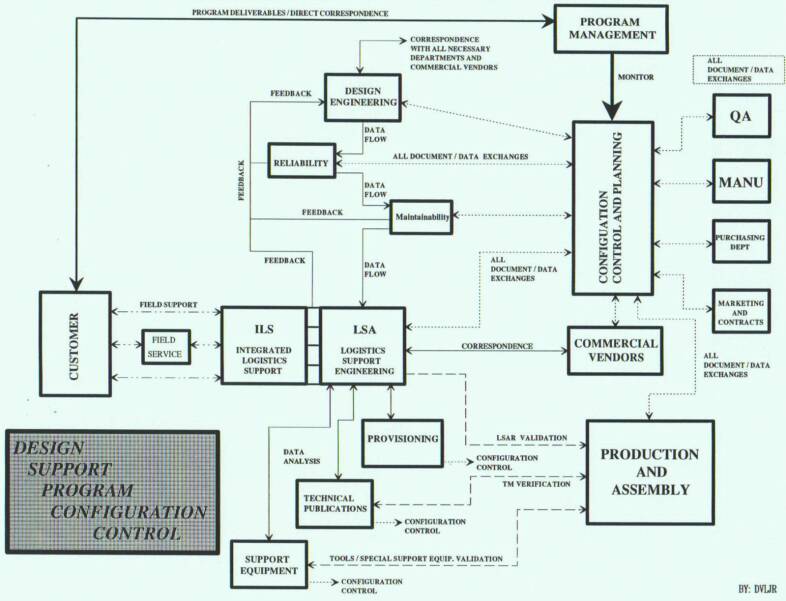

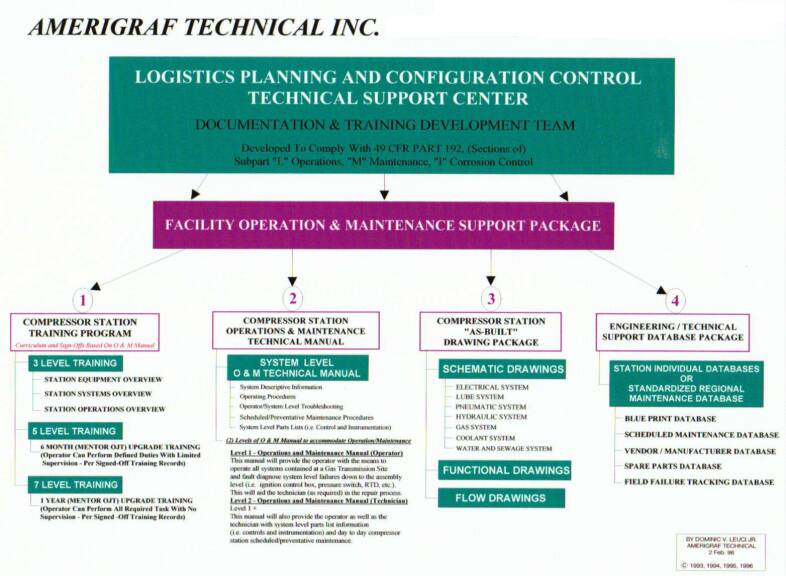

Typical Design Support Program - Configuration Control

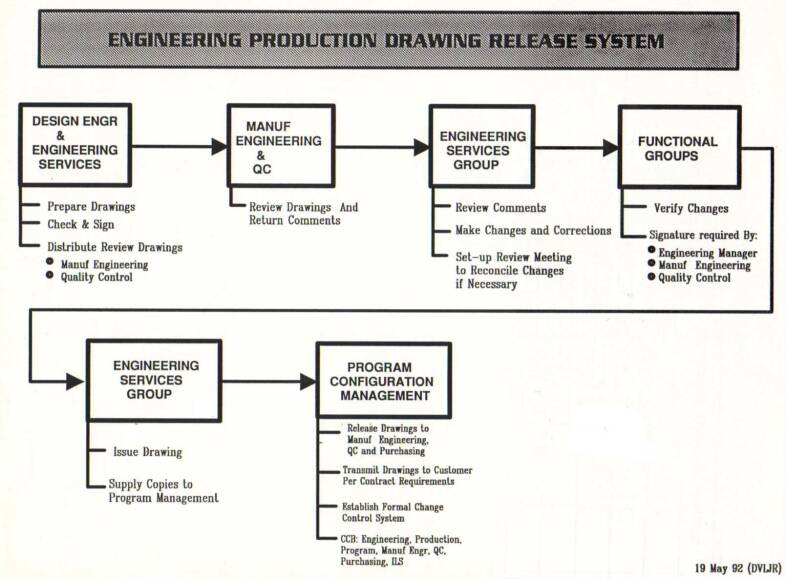

Typical Engineering Production Drawing Release System

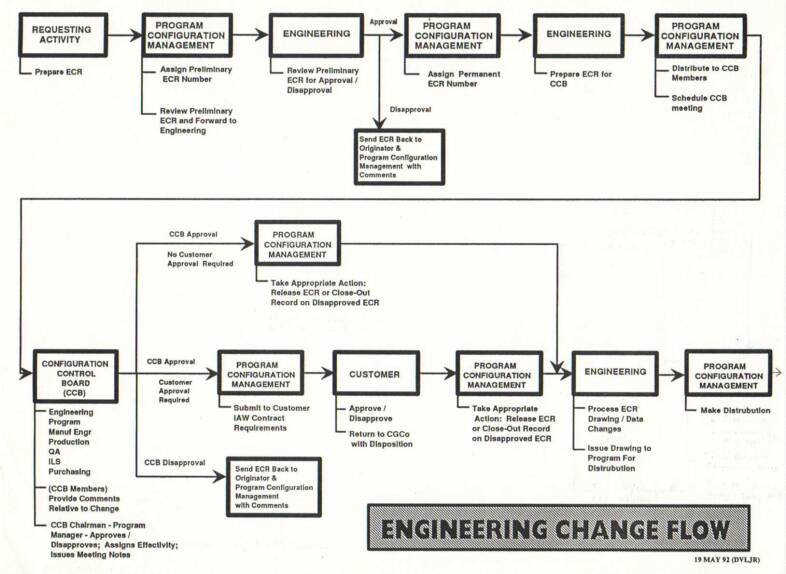

Typical Engineering Change Control Flow

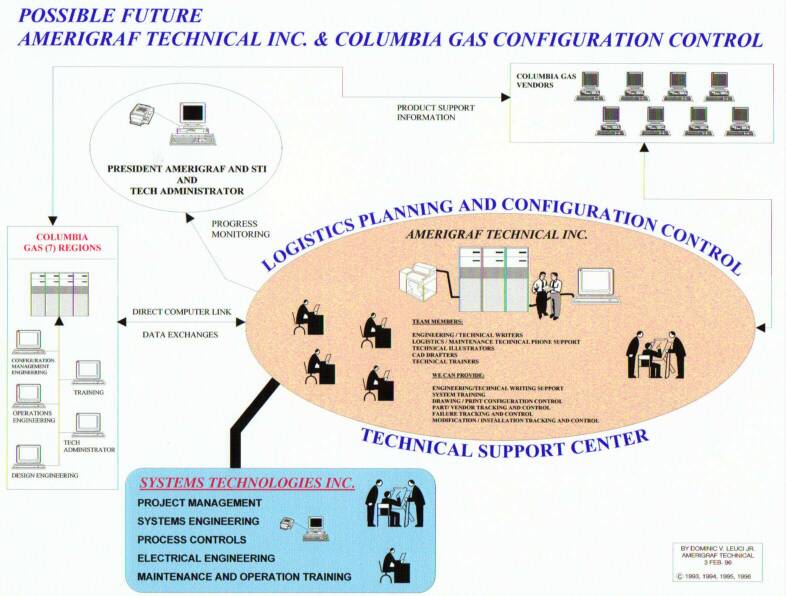

Proposed Configuration Control Plan

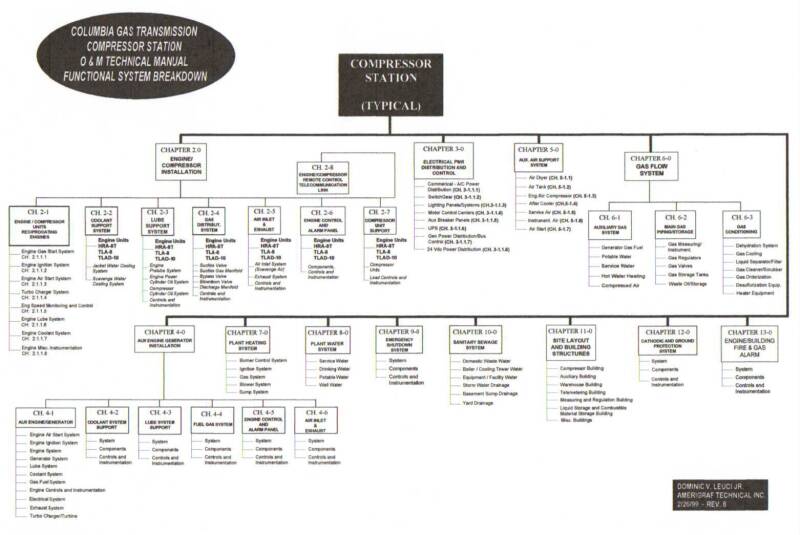

Compressor Station Functional System Breakdown

Proposed Logistics Planning and Configuration Control Technical Support Center

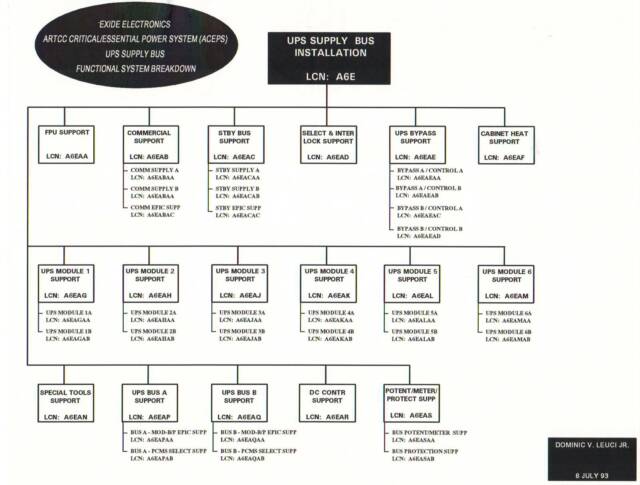

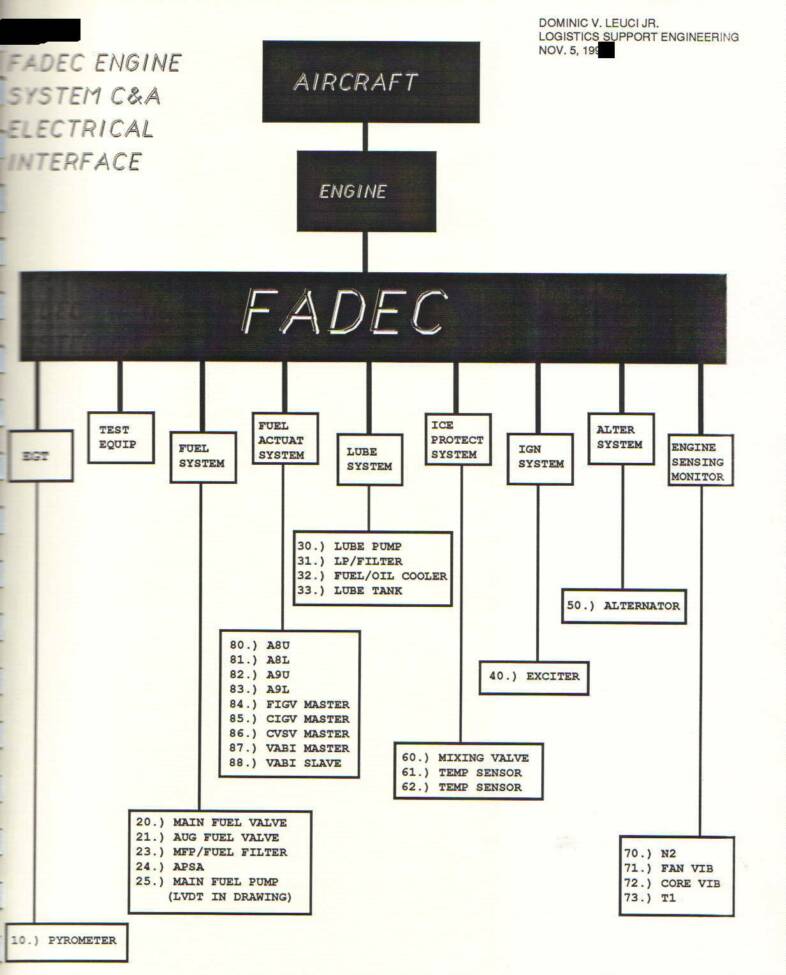

Typical System Functional Tree Breakdown

Typical System Functional Tree Breakdown

Website designed and hosted by AmeriGraf Technical Inc. ©2009 at Homestead

"We can no longer live with commonly accepted levels of delays, mistakes, defective materials, and defective workmanship. Transformation of Western management style is necessary to halt the continued decline of business and industry."

Dr. W. Edwards Deming

"Eliminate the need for mass inspection as the way of life to achieve quality by building quality into the product in the first place. Require statistical evidence of built in quality in both manufacturing and purchasing functions"

Dr. W. Edwards Deming

"End the practice of awarding business solely on the basis of price tag. Instead require meaningful measures of quality along with price."

Dr. W. Edwards Deming

"Institute innovation and constant improvement of product, service, and process. It is management's job to work continually on the system (design, incoming materials, maintenance, improvement of machines, supervision, training, retraining)."

Dr. W. Edwards Deming

"Improve constantly and forever every process for planning, production, and service. Search continually for problems in order to improve every activity in the company, to improve quality and productivity, and thus to constantly decrease costs."

Dr. W. Edwards Deming

"Institute modern methods of training on the job for all, including management, to make better use of every employee. New skills are required to keep up with changes in materials, methods, product and service design, machinery, techniques, and service."

Dr. W. Edwards Deming

"Adopt and institute leadership aimed at helping people do a better job. The responsibility of managers and supervisors must be changed from sheer numbers to quality."

Dr. W. Edwards Deming

"Break down barriers between departments and staff areas. People in different areas, such as Leasing, Maintenance, Administration, must work in teams to tackle problems that may be encountered with products or service."

Dr. W. Edwards Deming

"Eliminate the use of slogans, posters and exhortations for the work force, demanding Zero Defects and new levels of productivity, without providing methods. "

Dr. W. Edwards Deming

"Clearly define top management's permanent commitment to ever improving quality and productivity, and their obligation to implement all of these principles. Indeed, it is not enough that top management commit themselves for life to

quality and productivity.

They must know what it is that they are committed to—that is, what they must do. "

Dr. W. Edwards Deming

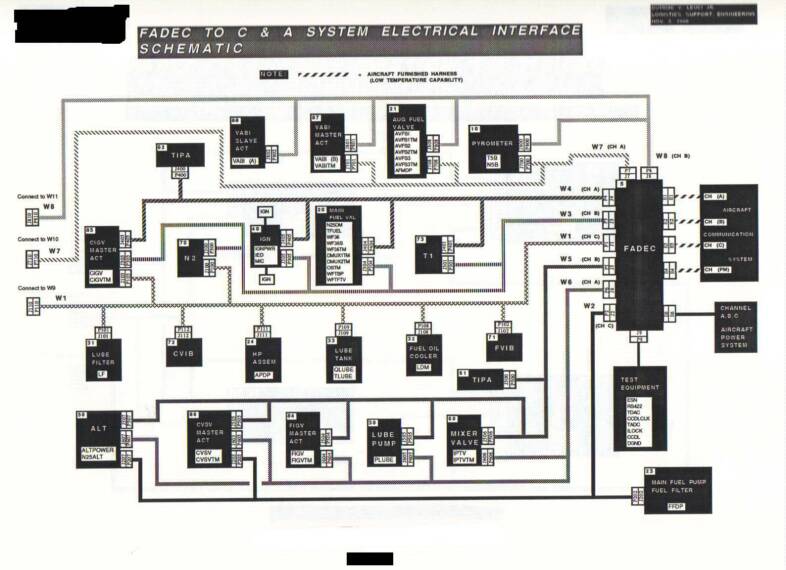

Typical Electrical Interface Schematic

"We can no longer live with commonly accepted levels of delays, mistakes, defective materials, and defective workmanship. Transformation of Western management style is necessary to halt the continued decline of business and industry."

Dr. W. Edwards Deming