SERVICES PROVIDED:

Project Lead / Senior Validation Engineer

(FDA Compliance Contract)

04/99 - 06/01

Two year capital expansion project:

- Developed customer packaging equipment specifications, qualifications and Factory Acceptance Test documentation IAW customer SOP’s, cGMP and FDA guidelines (21 CFR Part 11 and 210/211).

- Documentation developed includes: QAP, TP, FS, E/FRS, DDS, FAT, ECIQ, ECOQ, EIOQ, PQ for Thermoform & Coldform Blister Packaging Lines 31, 35, & 36 (approx. 50 documents per line) (approx. $20,000,000 worth of equipment).

- Equipment validation interfaced with the following customer departments/personnel: Project Engineer, Packaging Manager, Production, Quality Assurance, Computer Validation, System Administrator, Environmental Health & Safety, and Maintenance.

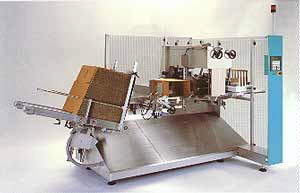

- Coordinated/qualified/validated two high speed blister packaging lines using the newly developed qualification protocols. Protocol executions included black box testing. Responsible for writing summary closure reports.

- Packaging equipment includes: an UHLMANN 1070 Blister Thermoformer and C2205, C2305, C2404 Cartoner, a PESTER vertical carton accumulator, a PESTER over-wrapper, case packer, palletizer, CCL labelers, INTERMEC printers, GARVEN check weighers to name a few.

- All documentation was developed on the customer Microsoft Network.

- All specifications and qualifications developed were standardized and utilized by customer to support worldwide packaging line expansion projects at additional customer site nationally and internationally, etc.

Validation Services

Web site designed & hosted by AmeriGraf Technical Inc. © 2009 at Homestead™